You Looking At Me? Scientists Develop Electronic-Eye Camera

Engineers John Rogers of the University of Illinois at Urbana-Champaign and Yonggang Huang of Northwestern University, Chicago have created an electronic eye-shaped camera that uses a new class of electronics technology that can conform to almost any shape of a human eye. The new retina-like camera sensor uses flexible photosensitive pixels.

"Using simple mechanics principles, the researchers have produced, for the first time, electronic devices on a hemispherical surface so that they can take images much like those captured by the human eye," said Ken Chong, advisor in the National Science Foundation (NSF) Engineering Directorate, who is one of the officers overseeing the researchers' National Science Foundation grant, in a statement.

John Rogers (pictured left), Flory-Founder chair professor of Materials Science and Engineering at University of Illinois at Urbana/Champaign, said the new camera he helped develop is based on the structure of the human eye. He said that the same technology can be used for a range of devices, including flexible sensors and prosthetics.

"This strategy opens up exciting, new engineering design possibilities by eliminating the two dimensional, planar constraints of conventional, semiconductor wafer-based optoelectronics," said Rogers.

Scientists said that since a flat, planar sensor cannot flex without damaging its light-sensitive pixels, the new technology puts the strain on the wires, each flexing as much as 40 percent. Since the wires absorb the strain, the pixels are barely stressed, even when affixed to the retina-shaped housing of the new experimental camera.

The technology bypasses a traditional planar sensor of adjacent pixels and instead relies upon an array of pixels interconnected by small wires, according to researchers. Using a flexible, temporary backing, the researchers can form the array into a curved shape and then transfer the array to its permanent location affixed to a glass lens.

"Mechanics helps to reduce the stresses and strain in components, and guide and optimize the system design," said Yonggang Huang (pictured left), Joseph Cummings professor of civil and environmental engineering and mechanical engineering, Northwestern University, who worked with his team to model the mechanical properties of the design so that it could be manufactured.

Conventional digital cameras use planar chips based on rigid, brittle semiconductor wafer substrates that fracture at strains of less than 1 percent, said the researchers.

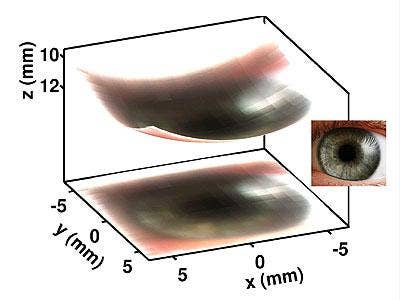

This is an actual image obtained using the new 256-pixel electronic eye camera. The curved surface rendering at the top corresponds to the image extracted directly from the camera, while a planar projection of the image appears below.

Instead of using a flat microchip as the light sensor for their new camera, the engineers developed a sensor that is a flexible mesh of wire-connected pixels. The mesh is made from many of the same materials as a standard digital-camera sensor, but has the unique ability to conform to convoluted, irregular surfaces.

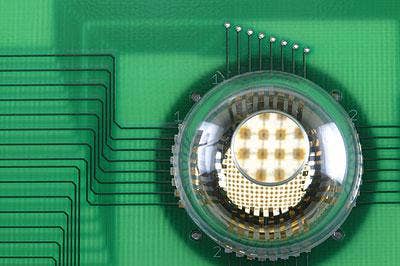

This picture was captured during the electronic eye fabrication process, and shows a silicon focal plane array (dark brown) and electronics on a hemispherical transfer element (translucent).

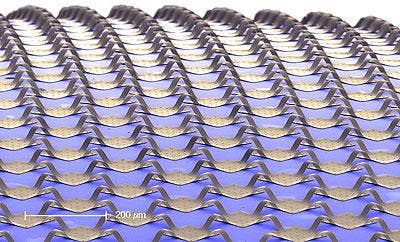

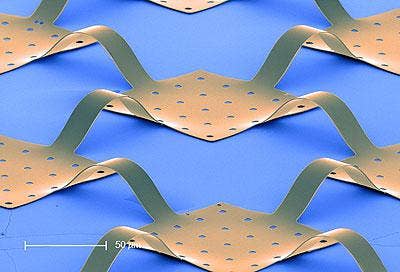

The scientists said that silicon photodetector pixels and electronics are interconnected by arc-shaped ribbons on a hemispherical substrate. These interconnects bow upward to accommodate the large mechanical strains needed to transform the planar layouts in which the systems are initially fabricated to the hemispherical geometries needed for implementation in the electronic eye. This image is colorized, and pixel elements and interconnects are shown in gold while the substrate appears in light blue.

The new system eliminates some of the aberrations caused by current camera designs and improves the quality of captured images, according to the engineers. The researchers are testing the same design principles in a range of other applications, including a thin, conformable monitor to detect electrical signals traveling across the undulating surface of the human brain.

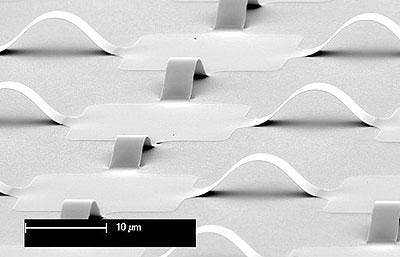

This is a close-up view of the silicon photodetector pixels and electronics interconnected by arc-shaped ribbons. The scale bar represents 10 micrometers (millionths of a meter), the scientists said.

"We believe that some of the most compelling areas of future application involve the intimate, conformal integration of electronics with the human body, in ways that are inconceivable using established technologies," said Rogers. "We are working actively with collaborators to explore possibilities in advanced health monitors, prosthetic devices and therapeutic systems.