Data Center Services Provider OneNeck Invents, Patents Robotic Heat, Humidity Sensor

Data center service provider OneNeck IT Solutions this week is touting the capabilities of a new patented rack cabinet robotic sensor that can automatically take detailed heat and humidity measurements on a per-"U" basis as a way to prevent heat spots from interrupting IT operations, especially in multi-tenant environments.

Other data center operators shouldn't expect to gain access to the technology any time soon, however, said Hank Koch, senior vice president of mission critical facilities for the Madison, Wis.-based provider of cloud, hosted, and other data center services.

OneNeck IT Solutions sees the technology as a true competitive advantage with its ability to automate the collection of heat and humidity sensor data in a non-intrusive fashion in multi-tenant environment, said Koch, who overseas operations in data centers in nine states, in an interview with CRN.

[Related: Emerging Vendors 2017: 20 Data Center Startups You Need To Know]

"We use it now to distinguish our services from others'," he said. "It's unique to us at the moment. But if there was a third party who wanted to work with us and license the patent, we would consider it."

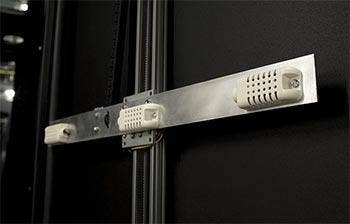

The robotic sensor, for which OneNeck IT Solutions received a U.S. patent in December, is a stand-alone device that mounts on the inside of the front or rear door of a data center rack cabinet. Racks that require extra sensor scrutiny can put one on both the front and back doors, Koch said.

The robotic sensor is mounted on a track which can stretch from top to bottom in a rack of up to 42U high, and travels up and down the track out of sight when the doors are closed to measure and record the heat and humidity U by U, Koch said. The data is recorded onto an on-board computer which a data center administrator can access via a Bluetooth-enabled smartphone app.

The administrator can set the sensor to automatically measure the data, or can manually control the collection of the data via the app, he said.

The sensor is useful in multi-tenant environments, Koch said.

"Large data centers like those owned by Google or Apple are not in colos or multi-tenant environments, and so the main security issue is to prevent outsiders from entering the facility," he said. "They don't have multiple tenants walking around the facilities.:

Co-location and multi-tenant environments, however, cannot be so easily locked down, Koch said.

"In colos and multi-tenant environments, you have different people walking around to check their equipment in cages or in locked or closed racks," he said.

Furthermore, while it is easy to measure and control the ambient temperature in an entire data center, it is much more difficult to do so at the rack level, Koch said.

"It is hard to see if the temperature of a more highly-dense component is impacting less-dense components," he said. "Or there may be 'bad hygiene' like cords and wires placed improperly. Or there may be poor use of blocking panels. So it's hard to determine what's happening in a cabinet and any impact on the components."

While administrators or tenants can open the door of a rack to check the temperature or humidity, doing so immediately changes the airflow in the rack and makes it hard to get an adequate reading, Koch said.

Another alternative is to put multiple sensors inside the cabinet, which would mean extra wires and extra installation time, he said.

OneNeck's robotic sensor was designed with Bluetooth, which allows it to easily exchange data and commands with a smartphone app, Koch said. The device could have been designed with Wi-Fi, but that would require an extra device to do the communication and would result in the possibility of increasing the electromagnetic interference inside the rack. The device could also be hard-wired, but that might raise customer concerns about security to have a cable passing data into and out of their racks, he said.

"The Bluetooth works only between the app and the robot," he said. "And the robot is the slave device, not the master."

Development of the robotic sensor started seven years ago after a particularly complex installation in which it was very difficult to pinpoint the cause of heating issues, Koch said.

"We could eyeball the environment and suggest different things," he said. "But we couldn't give a scientific response. We were going by gut feeling. That's not a good way to run a data center. We need data."

After that experience, the company turned to recent Iowa State graduates to study the problem, one of whom developed the robotic sensor, he said. However, the patent for the device is owned by OneNeck.