Behind The Scenes: A Look Inside Avnet's Global Solutions Center

Bringing Logistics To Life

Avnet opened its world-class, 228,000-square-foot Global Solutions Center (GSC) in Chandler, Ariz., to better address the integration and logistics needs of its solution provider partners. The facility gives Avnet the capability to build and ship more than 700,000 systems annually, allowing the Phoenix-based distributor to quickly and effectively fulfill integration requests of any scope.

CRN recently took a tour of the GSC. Here's what we found.

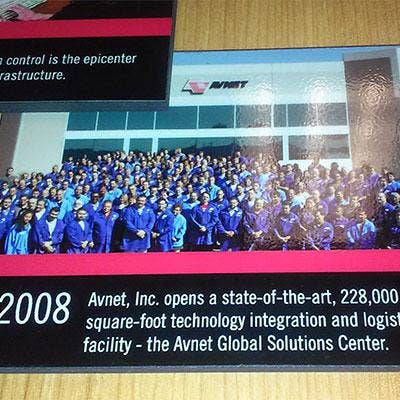

Making Partners Great Since 2008

Since opening in 2008, the GSC has given partners a hand with hardware integration, software configuration, packaging and logistics, and maintenance services. The facility can handle everything from basic services, such as hard-drive duplication, to advanced services, such as operating system installation to premium orders, such as touch-screen kiosks or OEM handheld device builds.

Living Avnet's Values

The GSC incorporates environmentally friendly features such as person-sensing technology for automatic control of lighting systems, reflective coating for the building's glass and a polyurethane-coated foam roofing system. The facility also recycles on average of one ton of cardboard per day.

Now Arriving At The GSC

The GSC has a dedicated inbound receiving area for fast and efficient receipt of products. The receiving area takes products pulled by Avnet's channel partners and separates cartons, scans for serial numbers and screens for defects. This allow Avnet's production team to focus on adding value to the software and hardware.

Avnet's relationship with key suppliers in the industry allows the distributor to get the products needed to design a solution regardless of platform.

Where Have All The Cartons Gone?

Avnet then takes all of these cartons and moves them around to the outbound area, allowing the distributor to optimize production flow. Implementing a new warehouse management system also has transformed the GSC into a completely digital, paperless environment.

A Place For Everything, And Everything In Its Place

Avnet has the ability to hold inventory in its 122,000-square-foot warehouse, enabling the distributor to store products for onging production. At any given moment, there's approximately $125 million of inventory and 19,000 SKUs on the GSC's shelves.

With 10,000 pallet locations, Avnet's team is in constant motion picking product and moving through aisles on wire-guided forklifts to ensure safety while providing prompt service.

Custom Design Fulfills Avnet's Need For Speed

Every inch of the warehouse's engineering space was built to Avnet's specification to provide the highest level of service. Because of the custom design, Avnet is able to optimize product flow through the warehouse and integration center, resulting in fewer touch points and reduced cycle times.

The distributor continues to streamline its processes by making strategic investments in cutting-edge equipment and industry-leading technology.

Where GSC's Magic Happens

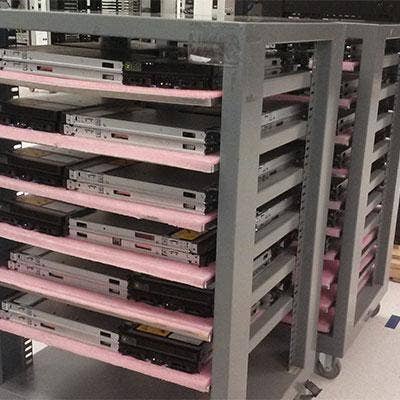

The GSC's 45,000-square-foot integration center has more than 125 technicians to assist solution providers with pre-sales support, quoting and full integration services, including hardware assembly, racking, cabling, device configuration and software loads. This allows Avnet's channel partners to enhance their capabilities and solution offerings without adding any infrastructure or staff.

Partners can expand their market reach to include customers with international requirements and more complex integration needs. The integration center can assist the channel with everything from a single customized solution to a volume solution for thousands of customers.

Hashing Out The Nuts And Bolts

The first step in the integration process for solution providers is to meet with Avnet's technical teams to review end-user project requirements, and determine best engineering and integration services. Once the requirements are identified, Avnet documents the processes and further refines it to minimize overall cycle times and make it as cost- and time-effective as possible.

By partenering with Avnet, channel partners can get their solutions integrated in just days, instead of weeks or months.

Configuring More Profit For Partners

Integration services can often be expensive, complicated or time-consuming for solution providers, but with the right distribution partner, they don't have to be.

Avnet offers a series of custom solutions to meet the needs of its customers and resellers. From simple to complex configurations, the distributor offers a series of build instructions and production methodologies than offer the fastest and most cost-effective solutions to everyone.

The distributor also offers a wide range of technical abilities and processes, including ISO, lean manufacturing and continuous improvement.

Software, Displays Also Benefit From Avnet's Touch

Avnet's custom software integration has continued to evolve as the market needs have changed. Today, Avnet has gone from operating system installs to custom application loading, and the company even offers remote access through its VPN network to ensure that the distributor can offer turnkey solutions to all of its partners and end users.

One of Avnet's customized service offerings is its display integration, where the distributor does touch screen, pixel screening, calibration and attached single-board computers. This has enabled Avnet to offer a full turnkey solution for partners that may have conventionally only required PC integration.

Exceeding The Industry Standard

Avnet meets standards such as ISSO 9001 for standard quality management systems, ISO 13485 for medical device manufacturers and ISO 14001 for the environment. Coupled with these ISO standards, Avnet's journey to continuous improvement remains strong through the efforts of its lean initiatives, its Kaizen events and Six Sigma.

Branded products sent through the GSC should, therefore, meet the reliability and quality expectations of solution providers, Avnet said.

Nursing Ailing Technology Back To Life

The GSC's 3,000-square-foot depot repair offers a standard one-year warranty on all the products that run through the integration center. The depot center does repairs on any component failures that the distributor identifies during production for its major suppliers, such as IBM and Hewlett-Packard.

The depot also offers a refurbishment service where Avnet takes the latest and greatest revisions and applies them to products that the company has already deployed in the field, enabling fresh technology for all of the distributor's customers.

The GSC also has a 3,000-square-foot first article lab and a 900-square-foot LED light lab.

From Integration To Packaging

Avnet's integration services don't end on the production floor. The distributor offers a wide variety of custom packaging solutions, ranging from overpack to custom label to safety applications that ensure all of the distributor's products arrive at customer sites defect-free and turnkey.

Deliver It Your Way

Avnet offers basic, advanced and premium packaging, and logistics services. Basic services include labeling and documentation, and private-label shipping, and advanced services include asset tagging, serialization and shrink-wrapping of pallets. Some of the premium orders involve custom carriers and shipping, as well as custom documentation and reporting.

Arrivederci Avnet

The GSC's dedicated outbound shipping area is in constant operation 24 hours a day. An average of 3,300 line items per day leave through eight dock doors. Avnet said it tries to ensure that its shipping operations provide superior quality to its customers.

Where Avnet's Converged Systems Are Born

The GSC's technology showcase currently features converged systems built by the distributor. The five main suppliers contributing to Avnet's multivendor converged solutions are Cisco, EMC, NetApp, Hitachi Data Systems and VCE.

Converged solutions are less expensive than the traditional single-vendor data center model, freeing up money for channel partners to invest in other areas of their operation, according to Denny O'Connell, Avnet's senior vice president and general manager for Converged and Data Solutions.

Turning The Silo Into A Commune

The traditional data center customer has their networking, security, server and data teams siloed off from one another, O'Connell said, which makes it difficult to configure a converged stack. O'Connell sees a wave of demand building for converged systems as technicians from various skillsets become more comfortable working in this type of architecture and cooperate more fully with one another.

Avnet has done a good job of putting together unified architecture on behalf of its partner community, with the solutions working exactly as intended, according to Brad Stocker, manager of sales engineering and architects for Converged and Data Solutions.

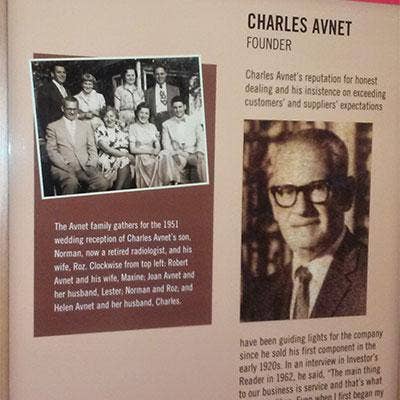

A Century Of New Ideas

Avnet was founded by Charles Avnet in 1921 as a seller of radio parts in downtown New York. The start of the Korean War in 1950 allowed Avnet's business to thrive as the company made electronic connectors for missile systems, airplanes and other applications.

The company was incorporated in 1955 and was added to the New York Stock Exchange five years later. At the time, Avnet began focusing on components such as capacitors, fasteners and switches.

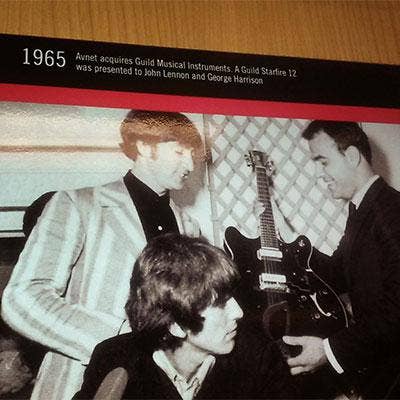

Avnet Jammed With The Beatles (Briefly)

Avnet moved beyond the industrial and military industries and into the consumer electronics market with the 1960 purchase of audio equipment company British Industries Corp. and the acquisition of Guild Musical Instruments five years later.

During that era, Avnet sold everything from guitars and perfume bottles to television antennas and die-casting machines, leading to an encounter with Beatles legends John Lennon and George Harrison.

But by the mid-1970s, an economic downturn had forced Avnet to sell off business units that didn't relate to its core mission of sales, warehouse and stocking facilities. That was also the time when Avnet began investing in electronics and computing technology, leading eventually to the Technology Solutions division.